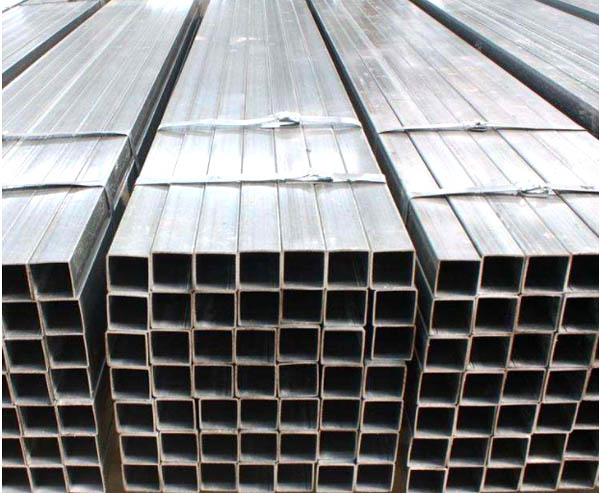

①细晶粒断口、低塑性,多发生于冷加工后的Q345B方管。原因在结晶退火或正火时,加热温度偏低或保温时间短,致使冷加工么过程中的破碎晶粒未能全部再结晶造成的。补救措施为:进行?f 晶退火,或进行一次完全退火或正火处理。

(1) Fine grain fracture and low plasticity occur mostly in Q345B square tube after cold working. The reason is that during crystallization annealing or normalizing, the heating temperature is low or the holding time is short, which results in the failure of recrystallization of the broken grains in the process of cold working. The remedial measures are as follows: annealing f crystal, or a complete annealing or normalizing treatment.

②硬度过髙对中碳钢而言,多为退火时加热温度过高,冷巧度太快,或等温温度过低等;另外错误采用了正火处理;对于Q345B方管进行球化退火时,欠热或过热均会造成退火后硬度高的缺?爸或者因冷却速度过快,等温温度过低或时间不足等。补救措 施:重新进行正火处理,如果组织合格,仅硬度高,则可进行一次 高温回火处理。

(2) For medium carbon steel, excessive hardness is mainly due to excessive heating temperature, too fast cooling, or too low isothermal temperature during annealing; in addition, incorrect normalizing treatment is used; for Q345B square tube, underheating or overheating will cause high hardness after annealing, Dad or due to excessive cooling speed, too low isothermal temperature or insufficient time, etc. Remedial measures: Renormalizing treatment, if the organization is qualified, only high hardness, you can carry out a high temperature tempering treatment.

③出现网状组织在共析钢中先共析铁素体或过共析钢中的共析渗碳体沿晶界呈网状分布,明显降低了Q345B方管材料的力学性能,原因?在于退火温度过高,或冷却速度过慢所造成的。补救措施:再进行 一次正火处理,对过共析钢正火后,应再进行一次高温回火,以改 善切削加工性能。

(3) The occurrence of reticulated structure in eutectoid steels with pre-eutectoid ferrite or eutectoid cementite in hypereutectoid steels shows a reticulated distribution along grain boundaries, which significantly reduces the mechanical properties of Q345B square tube material due to the excessive annealing temperature or slow cooling rate. Remedy: After normalizing the hypereutectoid steel, a high temperature tempering should be carried out again to improve the cutting performance.

④粗晶粒断口一是退火或正火加热温度太髙,加热时间长; 或经过5%?15%的变形冷加工的再结晶时间过长,造成晶粒的异?常粗大,出现粗晶粒断口,直接造成的力学性能和冲击韧性的降低。 补救措施:对亚共析钢采用正火或完全退火;对于过共析Q345B方管采用正?火+球化退火,或正火+髙温回火,对于晶粒度1?2号的Q345B方管材料必须 采用两次正火处理,第一次应高出正常温度50?150℃,但升温速度?要快,时间应尽可能的缩短,第二次则采用正常的正火温度。

(4) The first is that the annealing or normalizing heating temperature is too high and the heating time is too long; or the recrystallization time after 5%? 15% deformation and cold processing is too long, which results in the abnormal grain size and the appearance of coarse grain fracture, which directly reduces the mechanical properties and impact toughness. Remedial measures: normalizing or complete annealing for hypoeutectoid steel; normalizing + spheroidizing annealing or normalizing + tempering for hypereutectoid Q345B square pipe; twice normalizing for Q345B square pipe material with grain size 1?2, the first should be higher than normal temperature 50?150 C, but the heating rate should be faster, the time should be shortened as far as possible, and the second should be normal normalizing temperature. Degree.

⑤出现石墨碳出现于高碳和含硅、铝的钢中,原因为加热 温度过高,保温时间过长,使渗碳体分解而析出石墨,严重的将降?低材料的强度,脆性增大,是无法挽救的。

Graphite carbon appears in high carbon and steel containing silicon and aluminium. The reason is that the heating temperature is too high and the holding time is too long, which causes the cementite to decompose and precipitate graphite. Seriously, it will reduce the strength of the material and increase its brittleness, which is irreversible.

管理员

该内容暂无评论