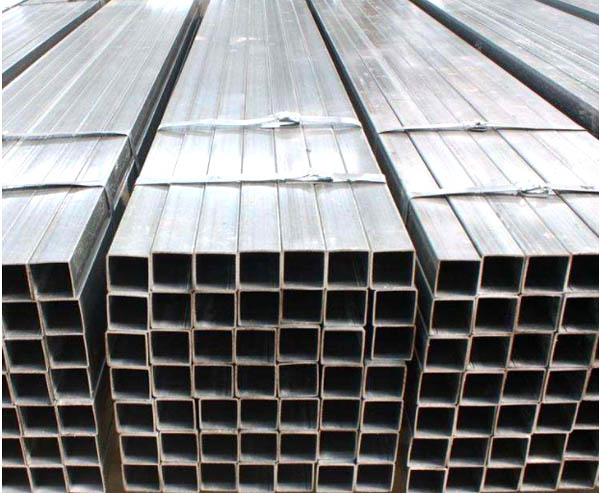

方管在制造过程中会出显不同的问题,采用不同方法制造出的方管出现的问题也是不同的,我们会根据出现的问题,采用合适的方法进行处理,以确保方管可以正常的使用,下面主要为大家介绍一下方管热处理后出现的质量缺陷。 方管经热处理后常见的质量缺陷有:淬火显微组织过热、欠热、淬火裂纹、硬度不够、热处理变形、表面脱碳、软点等,’它们对方管的使用寿命和精度具有重要的影响,分析芄产生的原因,对于指导热处理过程和预防有重要的作用。

Square pipe will show different problems in the manufacturing process, and the problems arising from different manufacturing methods are also different. We will adopt appropriate methods to deal with the problems, so as to ensure the normal use of Square pipe. The following is mainly about the quality defects of Square pipe after heat treatment. Common quality defects of square pipe after heat treatment are: quenching microstructures overheating, underheating, quenching cracks, insufficient hardness, heat treatment deformation, surface decarbonization, soft point, etc.'They have important influence on the service life and accuracy of square pipe. Analyzing the causes of the formation of Juan has an important role in guiding the heat treatment process and prevention.

1、方管过热:

1. Square tube overheating:

从方管粗糙口上可观察到淬火后的显微组织过热情况。但i 要确切判断其过热的程度,必须观察显微组织。如果GCrl5钢的淬火组织中出现粗针状马氏体,则为淬火过热组织。形成原因可是淬火加热温度过高或加热保温时间太长造成的全面过热;也可肖巨是因原始组织带状碳化物严重,在两带之间的低碳区形成局部马氏体针状粗大,造成的局部过热。过热组织中残留奥氏体增多,尺寸稳定性下降。由于淬火组织过热,钢的晶体粗大·会导致方管的核J 性下降·抗冲击性能降低,方管的寿命也降低。过热严重甚至会造成淬火裂纹。

Overheating of quenched microstructures can be observed from the rough mouth of square tubes. However, in order to determine the degree of overheating, we must observe the microstructures. If coarse acicular martensite appears in the quenched structure of GCrl5 steel, it is quenched superheated structure. The reason is that the quenching heating temperature is too high or the heating holding time is too long, which results in the overall overheating. It can also be said that Xiao Ju is the local overheating caused by the formation of local martensite needle-like coarseness in the low-carbon zone between the two zones due to the serious ribbon carbides in the original structure. The retained austenite in the superheated structure increases and the dimensional stability decreases. Due to the overheating of quenched structure, the coarse crystal of steel will lead to the decrease of core J property, impact resistance and service life of square tube. The severe overheating may even cause quenching cracks. 2、方管热处理变形:

2. Heat treatment deformation of square pipe:

方管在热处理时,存在有热应力和组织应力,这种内应力能相互叠加或部分抵消,是复杂多变的,因为它能随着加热温度、加热速度、冷却方式、冷却速度、零件形状和大小、装炉的方式的变化而变化,故其热处理变形是难免的。认识和掌握它的变化规律可以使轴承零件的变形(如合金管的椭圆、尺寸胀大等)置于可控的范围,有利于生产的正常进行。当然在热处理过程中的机械碰撞也会使零件产生变形,但这种变形是可以通过改进操作等来加以减少和避免的。

There are thermal stress and organizational stress in square tube during heat treatment. The internal stress can be superimposed or partially offset each other, which is complex and changeable. Because it can change with the change of heating temperature, heating speed, cooling mode, cooling speed, shape and size of parts, and charging mode, the heat treatment deformation of square tube is unavoidable. Understanding and mastering its changing law can make the deformation of bearing parts (such as the ellipse of alloy tube, size expansion, etc.) in a controllable range, which is conducive to the normal production. Of course, mechanical collision in the heat treatment process will also cause deformation of parts, but this deformation can be reduced and avoided by improving operation.

3、方管软点:

3. Soft spot of square pipe:

多半是由于加热不足、冷却不良或淬火操作不当等原因造成的方管表面局部硬度不够的现象称为淬火软点。它像表面脱碳一样可以造成表面耐磨性和疲劳强度的严重下降,使用过程中将造成局部剧烈磨损或失效。

The phenomenon that the local hardness of square tube surface is not enough due to insufficient heating, poor cooling or improper quenching operation is called quenching soft point. Like surface decarbonization, it can cause serious decrease in wear resistance and fatigue strength of the surface, which will cause severe local wear or failure during use.

方管在热处理时出现的问题,我们会对方管进行深刻的研究,把方管的的质量保证可以合理的利用。我们把方管制作成型后,会对方管进行全方位的检测,让方管的质量得以保证,在实际运用中让顾客满意。

We will make a deep study of the problems that occur in the heat treatment of square pipes, so that the quality assurance of square pipes can be reasonably utilized. After forming the square tube, we will carry out all-round inspection of the square tube, so that the quality of the square tube can be guaranteed and the customers can be satisfied in practical application.

管理员

该内容暂无评论