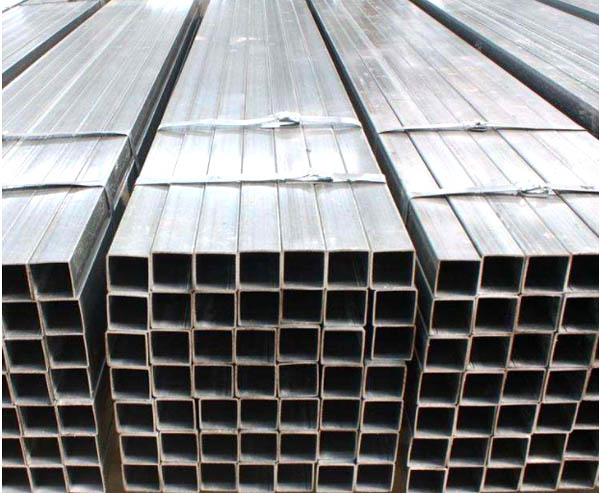

让现已加工成制品方管具有较小曲折度还得依靠机械东西校直机来完结。所以为了消除方管曲折,一切方管都需求经过冷校直。方管曲折是因为轧机调整不妥,轧制时残留的剩余应力以及因为沿管子截面和长度上冷却不平等缘由形成的。因而,不行能从轧机直接得到很直的管子,只要通过冷校直管子的曲折度才干满意技能条件的规则。

To make the square tubes of the products processed now have a small degree of flexibility, we have to rely on the mechanical straightening machine to complete the straightening machine from east to west. Therefore, in order to eliminate the twists and turns of square tubes, all square tubes need to undergo cold straightening. The bending of square pipe is caused by improper adjustment of rolling mill, residual stress during rolling and unequal cooling along the section and length of pipe. Therefore, it is impossible to get very straight pipes directly from the rolling mill. Only by cold straightening the pipe's flexibility can the rules of skill conditions be satisfied.

校直的根本道理即是使方管进行弹塑性曲折,由大的曲折度成为小的曲折度,因而钢管在校直机内有必要遭到重复曲折。而钢管重复曲折的程度主要由校直机的调整所决议。

The basic principle of straightening is to make square pipe elastic-plastic twist, from large twist to small twist, so it is necessary for steel pipe to be repeated twist in straightening machine. The degree of repeated twists and turns of steel pipe is mainly determined by the adjustment of straightening machine.

影响校直质量的要素许多,如原管的曲折度,钢管尺度和材料校直机型式,调整参数等。

There are many factors affecting the quality of straightening, such as the bending degree of the original pipe, the size of the steel pipe and the type of straightening machine for materials, and the adjustment of parameters.

管理员

该内容暂无评论