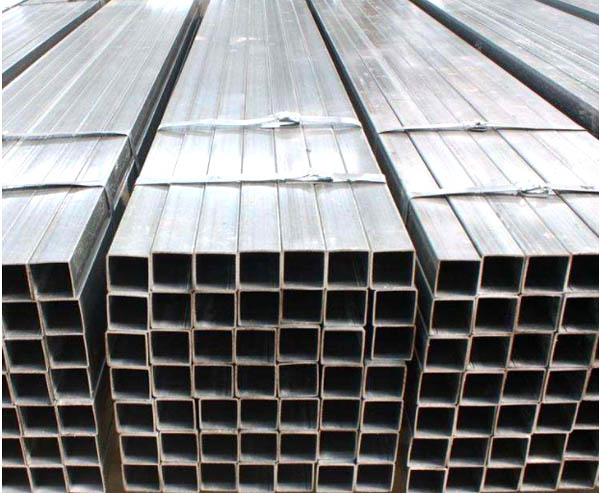

热镀锌方管是目前钢材市场上应用非常普遍的品种,随着镀锌技术的进步与镀锌方管应用的推广,对热镀锌方管表面质量的要求也越来越高。其锌层厚度一般在Z80~Z140之间,其基本控制要点是:

Hot-dip galvanized square tubes are widely used in steel market at present. With the progress of galvanizing technology and the popularization of galvanized square tubes, the requirements for surface quality of hot-dip galvanized square tubes are becoming higher and higher. Its zinc layer thickness is generally between Z80 and Z140. Its basic control points are as follows: 1、加工速度

1. Processing speed

对于普通镀锌产品而言,随着带钢厚度降低而生产速度提升。但对于高表面 热镀锌方管,生产速度提高后,由于其锌层厚度较薄必然导致气刀压力加大,带钢锌流纹缺陷则愈加严重。

For common galvanized products, the production speed increases with the reduction of strip thickness. However, for high surface galvanized square pipe, with the increase of production speed, the pressure of air knife will increase because of the thinner zinc layer, and the zinc rheological defect of strip steel will become more serious.

经过生产分析认为带钢厚度在0.7mm以上时生产速度与带钢厚度呈反比。0.6mm以下时应适当降低生产速度。

The production analysis shows that when the strip thickness is over 0.7mm, the production speed is inversely proportional to the strip thickness. The production speed should be reduced properly below 0.6mm.

2、锌流纹问题

2. Zinc Ribbon Problem

锌流纹问题是高表面 热镀锌方管生产中的主要问题。锌流纹问题产生的根本原因为锌锅中Al的产生。

Zinc rubbing is the main problem in the production of high-surface hot-dip galvanized square tubes. The root cause of zinc ripple problem is the production of Al in zinc pot.

1) 对酸轧联机的要求。

1) Requirements for acid rolling on-line.

反射率60%以下,无论镀锌机组清洗段如何控制,Al含量均不能低于0.22%;反射率60 -80%,在增加镀锌机组清洗段电导率前提下,Al含量可以降低至0.16-0.22%。

Aluminum content can not be lower than 0.22% no matter how the cleaning section of galvanizing unit is controlled, and the reflectivity is 60-80%. Aluminum content can be reduced to 0.16-0.22% under the premise of increasing the conductivity of cleaning section of galvanizing unit.

2 ) 对镀锌机组清洗段要求。

2) Requirements for cleaning section of galvanizing unit.

需要镀锌机组清洗段增大清洗能力对残留物进行处理。一般电解段要求不低于60ms/cm,涮洗段不低于45ms/cm,即可对冷硬板表面洗净。

It is necessary to increase the cleaning capacity of the cleaning section of galvanizing unit to deal with the residues. Normally, the electrolysis section should be no less than 60 ms/cm and the rinsing section should be no less than 45 ms/cm, so that the surface of the cold and hard plate can be washed.

3) 带钢入锌锅温度

3) Temperature of strip into zinc pot

对于常规规格带钢人锌锅温度控制在(465±5℃) 即可,但是对于薄规格、薄锌层产品(0 0.4mm,Z80),此温度下带钢表面出现严重流纹和锌层微裂纹。当带钢温度降低至440℃或提高至490℃时均可以将锌裂纹基本消除。但是考虑到锌流纹问题, 490℃最为合适 。

For conventional strip steel, the temperature of zinc pot can be controlled at (465 +5 C), but for thin strip steel and zinc layer products (0.4mm, Z80), serious ripple and zinc layer micro-cracks appear on the surface of strip steel at this temperature. Zinc cracks can be basically eliminated when the strip temperature is reduced to 440 or increased to 490 C. But considering the zinc rheological problem, 490 (?) C is the most suitable temperature.

3、光整机问题

3. Finishing Machine Problem

带钢在经过光整机时,在轧制力作用下发生带钢长度、宽度方向上金属流动。当宽度方向上金属流动受阻或者流动不一致,带钢出现暗纹。主要采取:

When the strip passes through the finishing machine, metal flow occurs in the direction of strip length and width under the action of rolling force. When the metal flow is blocked or inconsistent in the width direction, dark strip appears. Mainly adopt:

1) 加大光整机前后张力。

1) Increase the tension of the finishing machine.

2) 提高光整机防皱辊高度,并随着带钢减薄而增加高度。

2) Increase the height of wrinkle-proof roll of finishing machine, and increase the height with the strip thinning.

4、其他

4, others

除上述几点外。镀锌机组辊面清洁、辊系位置偏差、退火炉内氢气含量等常规项目也直接影响带钢表面状态。因此建议生产前使用过渡卷提前按照设计工艺参数执行,并利用油石打磨手段进行生产评估。

In addition to the above points. Conventional items such as roll surface cleaning, roll system position deviation and hydrogen content in annealing furnace also directly affect strip surface condition. Therefore, it is suggested that the transition coil be used before production according to the design process parameters in advance, and the production evaluation should be carried out by means of oil stone grinding.

管理员

该内容暂无评论