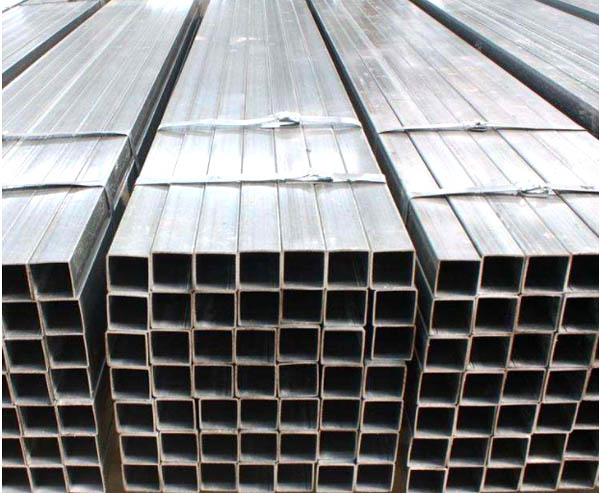

在我国镀锌方管分为热浸镀锌和电镀锌。热浸镀锌层厚,涂层均匀,附着力强,使用寿命长。电镀成本低,表面不光滑,耐腐蚀性比热浸镀锌管差。镀锌方管:热镀锌方管方管基板与熔融电镀液复合物理、发生化学反应,形成致密的锌铁合金层耐腐蚀结构。合金层与纯锌层、方管衬底集成在一起。因此,其耐腐蚀性强。

In China, galvanized square tubes are divided into hot dip galvanizing and galvanizing. Hot dip galvanizing has thick coating, uniform coating, strong adhesion and long service life. The electroplating cost is low, the surface is not smooth and the corrosion resistance is worse than that of hot dip galvanized pipe. Galvanized square tube: The hot-dip galvanized square tube square tube base plate and the melt electroplating solution complex physical, chemical reaction, forming a compact zinc-iron alloy layer corrosion-resistant structure. The alloy layer is integrated with pure zinc layer and square tube substrate. Therefore, it has strong corrosion resistance.

镀锌方管:冷镀锌方管锌层是电镀层,锌层与方管基板分开分层。锌层很薄,锌层简单地附着在方管基板上,很容易脱落。因此,其耐腐蚀性差。在新家中,禁止使用冷镀锌方管作为供水管。

Galvanized square pipe: The galvanized layer of cold galvanized square pipe is electroplated, and the zinc layer is separated from the square pipe substrate. The zinc layer is very thin. The zinc layer is simply attached to the square tube substrate, which is easy to fall off. Therefore, its corrosion resistance is poor. It is forbidden to use galvanized square pipes as water supply pipes in new homes.

方管镀锌的几种方法

Several methods of galvanizing square tubes

方管电镀锌:由于电解过程,在盐溶性的锌电极中,可以进行电子化。合伙和锌正在下沉到管子的表面。这样做得很好。然而,这种管道的粘性不足以阻挡持久的凝聚,多孔表面限制了管控寿命五年。

Square tube galvanizing: Due to the electrolysis process, it can be electronized in salt-soluble zinc electrodes. Partnership and zinc are sinking to the surface of the pipe. It's done very well. However, the viscous properties of such pipes are insufficient to prevent persistent condensation, and the porous surface limits the control life for five years.

方管热镀锌:这是一种昂贵的方法,但它的帮助是最耐用的,尽管还不够,所以需要额外的机械加工。热镀锌是用镀锌锌上镀锌的过程。不是所有的钢码都可以被这样处理:如果碳含量超过了0.24%,这种镀锌法是不合适的。

Hot-dip galvanizing of square tubes: This is an expensive method, but its help is the most durable, although not enough, so additional mechanical processing is required. Hot-dip galvanizing is a process of galvanizing on galvanized zinc. Not all steel codes can be treated in this way: if the carbon content exceeds 0.24%, this galvanizing process is not appropriate.

方管热扩散涂层:在水管表面的密封容器中,有一对锌的蒸汽。在这种情况下,在热离心机过程中形成的保护层是非常强大和平稳的,无论管道配置的复杂性,它几乎是不存在的。在焊接时有一种稀有的东西。镀锌管的服役期为15年,这是值得的,因为表面上没有锌光泽。

Square pipe thermal diffusion coating: There is a pair of zinc vapors in the sealed container on the surface of the water pipe. In this case, the protective layer formed in the thermal centrifuge process is very strong and stable, regardless of the complexity of pipeline configuration, it almost does not exist. There is something rare in welding. The service life of galvanized pipes is 15 years, which is worthwhile because there is no zinc gloss on the surface.

方管冷镀锌:这种方法适用于已经运行的沟通,并代表人工染料,含有锌、手工或气体。这是一个拥抱。这种涂层有时并不是热镀镀,但不需要拆卸,尽管机械的可持续性是不可思议的。以下是:在第一种情况下,不超过5到6年,在第二种情况下,使用时间增加到7到8年。

Square tube cold galvanizing: This method is suitable for communication already in operation, and represents artificial dyes, containing zinc, manual or gas. It's a hug. Sometimes this coating is not hot-dipped, but it does not need to be disassembled, although the mechanical sustainability is incredible. The following are: in the first case, no more than 5 to 6 years, in the second case, the use time increased to 7 to 8 years.

管理员

该内容暂无评论