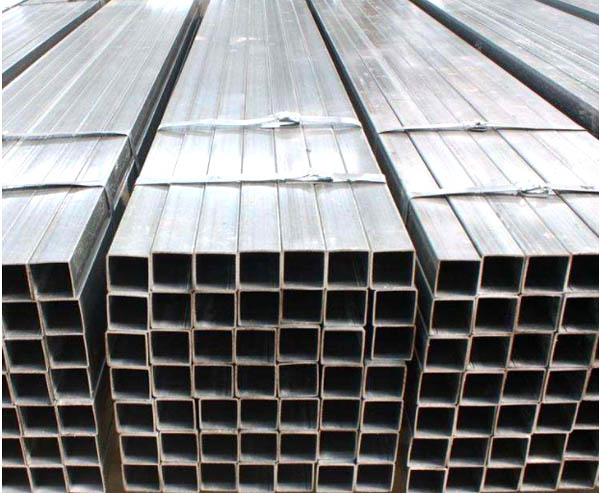

变形首先是焊接Q345B方管的焊接应力的存在的问题,方管加工时刻及加工机械节省 因为精度精确,外表状况良好,冷拉钢商品可直接运用,如喷涂、打砂,折弯,钻孔也可按实践需求精拉以后直接电镀,免去了很多加工。 如果想降低变形量或达到理想的尺寸误差范围,首先就焊接时的工件的工装及焊接顺序是必须的,每个焊接完的工件都有焊接内应力,如果想消除有以下几种方式:

Deformation is the problem of welding stress in welding Q345B square pipe. The processing time and processing machinery of square pipe are saved because of its precise accuracy and good appearance. Cold-drawn steel products can be directly used, such as spraying, sanding, bending, drilling and direct electroplating after finishing drawing according to practical requirements, which eliminates a lot of processing. If you want to reduce the deformation or achieve the desired size error range, first of all, the assembly and welding sequence of the workpiece during welding is necessary. Every welded workpiece has welding internal stress. If you want to eliminate the following ways:

1.自然时效,热处理,振动时效。自然时效已经不能适应大多数方管厂家的生产要求,周期太长。

1. Natural ageing, heat treatment, vibration ageing. Natural aging has been unable to meet the production requirements of most factories, and the cycle is too long.

2.使用热处理,热处理是一种效果较明显的去除焊接应力的方式,好多方管厂家其耗费大量的资金也是望而却步,振动时效因为其携带方便,经济适用,效果明显深受各大机械加工客户的青睐。它是通过高频振动的方式是金属内部的晶体滑移,使其重新分布从而达到内应力的相互抵消,保证工件的尺寸精度。

2. Using heat treatment, heat treatment is a more effective way to remove welding stress. Many factories are discouraged because of the large amount of money they consume. Vibration stress relief is easy to carry, economical and applicable, and the effect is obviously favored by the major mechanical processing customers. It is through the way of high frequency vibration that the crystals inside the metal slip and redistribute so as to achieve the mutual counteraction of internal stress and ensure the dimensional accuracy of the workpiece.方管泛应用于机械制造、轻工、五金、标准件、自行车、轿车、摩托车、纺织机械、变压器及其他机械行业。 冷拉方钢形状标准多样性。 经过设计不一样形状的模具,冷拉出不一样截面形状、不一样大小标准公役。视点可设制成直角或圆角。 高精确度。 运用高质量的硬质合金模具以及拥有专业技能人员,公役精确、一致。 外表润滑。 领先的冷拉工艺使冷拉钢商品外表润滑明亮。 资料很多节省。 冷拉钢是将原资料冷挤压变形达到需的形状、所需求的标准及公役,原材的耗损极少,相对运用传统车床机加工切削所损耗的资料,冷拉 钢所节省的资料对错常可观的,特别当资料用量大,资料本钱的节省更为明显。

Commodities are widely used in machinery manufacturing, light industry, hardware, standard parts, bicycles, cars, motorcycles, textile machinery, transformers and other mechanical industries. Diversity of shape standards for cold drawn square steel. After designing different shapes of dies, different cross-section shapes and sizes of standard public service can be drawn out by cold drawing. Viewpoints can be set to right or round corners. High accuracy. The use of high quality cemented carbide die and professional skilled personnel, public service accurate and consistent. Appearance lubrication. Leading cold-drawing process makes the appearance of cold-drawn steel products lubricated and bright. A lot of information is saved. Cold-drawn steel is the raw material cold extrusion deformation to meet the required shape, required standards and public service, the loss of raw material is very small, compared with the use of traditional lathe cutting loss of information, the data saved by cold-drawn steel is often considerable, especially when the amount of data is large, the saving of data cost is more obvious.

管理员

该内容暂无评论