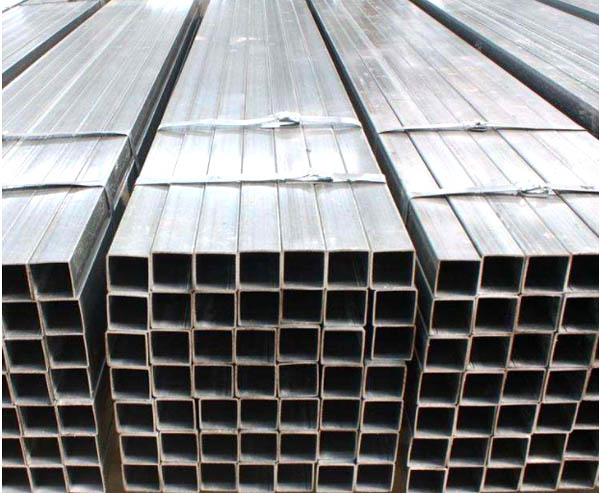

冷弯方管、冷弯矩形管是通过外辊与管坯外壁的单向接触形成弯矩使带料弯折,冷弯会使弯折线产生压缩,压缩效应使弯折线纵向伸长,弯折处金属出现堆积变厚,这就是冷弯的压缩/增厚效应。

Cold-formed square pipe and cold-formed rectangular pipe bend the strip through the unidirectional contact between the outer roll and the outer wall of the billet. Cold-formed bend will compress the bending line. The compression effect will make the bending line lengthen longitudinally, and the metal at the bend will accumulate and become thicker. This is the compression/thickening effect of cold-formed. 1)冷弯的优点是反弹小,成型准确,而且只要辊型准确,内角成型的R比较准确。冷弯的优点是可以在无法进行冷弯时进行边长的弯折,比如方矩管的上边/侧边同步弯折和精整。冷弯还可以弯折R<0.2t的内角而不致管壁发生断裂。

1) The advantages of cold bending are small rebound, accurate forming, and as long as the roll shape is accurate, the R of inner corner forming is more accurate. The advantage of cold bending is that it can bend side length when cold bending is not possible, such as synchronous bending and finishing of the upper/side of square tube. Cold bending can also bend the inner angle of R < 0.2T without breaking the pipe wall.

2)冷弯的缺点是有拉伸/减薄效应。冷弯会使弯折处产生拉伸,拉伸效应使弯折线纵向的长度缩短; 第二,冷弯弯折处金属会因拉伸而变薄。冷弯的缺点是在上边/侧边同步冷弯时,由于上辊和下辊同时产生压力,成型力容易超越临界点,造成边部失稳内凹,并且也会影响到机组稳定运行和成型质量。

2) The disadvantage of cold bending is the stretching/thinning effect. Cold bending causes tension at the bending point, which shortens the longitudinal length of the bending line. Secondly, the metal at the cold bending point will become thinner due to tension. The disadvantage of cold bending is that when upper/side synchronous cold bending occurs, the forming force is easy to exceed the critical point due to the simultaneous pressure of upper and lower rolls, resulting in the instability of edge concave, and also affecting the stable operation and forming quality of the unit.

这也是方管和矩形管冷弯成型时不同的特点。冷弯方管、矩形管广泛应用在各大行业,例如:

This is also the different characteristics of square tube and rectangular tube in cold bending forming. Cold-formed square and rectangular tubes are widely used in various industries, such as:

第一、矿用支撑架焊接方管、矩形管,标准号我GB/T14291-2000。代表材质Q235A、B级钢.主要用于矿山压风、排水、轴放瓦斯用直缝焊接方管。

First, welding square and rectangular pipes with mine support frame, standard No. I GB/T 14291-2000. The representative material Q235A, B grade steel. Mainly used for mine air pressure, drainage, shaft gas drainage with straight seam welding square pipe.

第二、船舶、码头、空港物流作业设备用冷弯方管、矩形管,代表材质Q345A、B、C、D、E级钢和16Mn锰钢.主要用于船舶龙门吊、船舶制造、塔吊、塔机、高空作业设备等。

Secondly, cold-formed square and rectangular pipes for ship, wharf and airport logistics equipment, which represent Q345A, B, C, D, E grade steel and 16Mn manganese steel, are mainly used for gantry crane, ship manufacturing, tower crane, tower crane and aerial operation equipment.

第三、钢结构、幕墙结构用方管、矩形管,代表材质Q235A、B级钢和Q345A、B级钢.主要用于大型钢结构制造、工程结构、建筑施工、桥梁制造、码头工程等项目建筑施工。

管理员

该内容暂无评论