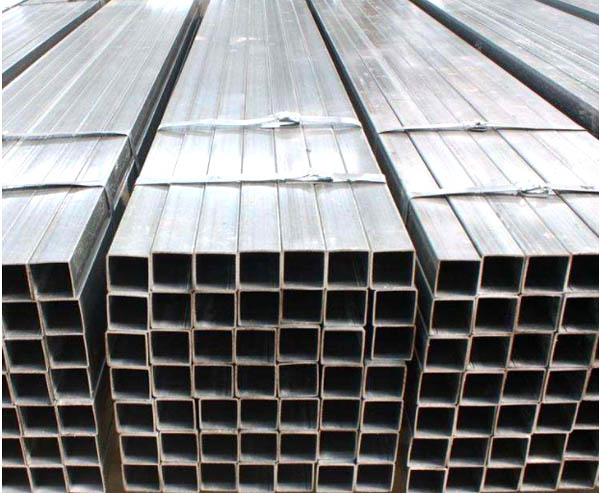

镀锌方管,顾名思义,就是表面镀有锌的方形管材。方管,是方形管材的一种称呼,也就是边长相等的的钢管。是带钢经过工艺处理卷制而成。一般是把带钢经过拆包,平整,卷曲,焊接形成圆管,再由圆管轧制成方形管然后剪切成需要长度。一般是50根每包。

Galvanized square pipe, as its name implies, is a square pipe with galvanized surface. Square pipe is a form of address for square pipe, that is, steel pipe with equal side length. The strip is coiled by process treatment. Generally, strip steel is unpacked, flattened, coiled, welded to form a circular pipe, then rolled into a square pipe from the circular pipe and cut into the required length. Usually 50 pieces per bag.

方管有无缝和焊缝之分。

There are seamless and welded square pipes.

无缝方管是一种具有中空截面,周边没有接缝的长条钢材。钢管具有中空截面,大量用作输送流体的管道,如输送石油、天然气、煤气、水及某些固体物料的管道等。钢管与圆钢等实心钢材相比,在抗弯抗扭强度相同时,重量较轻,是一种经济截面钢材,广泛用于制造结构件和机械零件,如石油钻杆、汽车传动轴、自行车架以及建筑施工中用的钢脚手架等。用钢管制造环形零件,可提高材料利用率,简化制造工序,节约材料和加工工时,如滚动轴承套圈、千斤顶套等,目前已广泛用钢管来制造。钢管还是各种常规武器不可缺少的材料,枪管、炮筒等都要钢管来制造。钢管按横截面积形状的不同可分为圆管和异型管。由于在周长相等的条件下,圆面积最大,用圆形管可以输送更多的流体。此外,圆环截面在承受内部或外部径向压力时,受力较均匀,因此,绝大多数钢管是圆管。但是,圆管也有一定的局限性,如在受平面弯曲的条件下,圆管就不如方、矩形管抗弯强度大,一些农机具骨架、钢木家具等就常用方、矩形管。

Seamless square pipe is a kind of long steel with hollow section and no joint around it. Steel pipe has hollow section, which is widely used as pipeline for conveying fluids, such as oil, natural gas, gas, water and some solid materials. Compared with solid steels such as round steel, steel pipe has lighter weight when its bending and torsion strength is the same. It is an economic section steel. It is widely used in manufacturing structural and mechanical parts, such as oil drill pipe, automobile transmission shaft, bicycle frame and steel scaffolding used in construction. Manufacturing ring parts with steel pipes can improve material utilization, simplify manufacturing process, save material and processing time, such as rolling bearing rings, Jack sleeves and so on. At present, steel pipes have been widely used in manufacturing. Steel pipe is also an indispensable material for all kinds of conventional weapons. Tubes, barrels, etc. are made of steel pipe. Pipe can be divided into circular pipe and special-shaped pipe according to the shape of cross-section area. Because the circular area is the largest under the condition of equal circumference, more fluid can be transported by the circular pipe. In addition, when the ring section is subjected to internal or external radial pressure, the force is more uniform, so the vast majority of steel tubes are circular tubes. However, the circular pipe also has some limitations. For example, under the condition of plane bending, the circular pipe is not as strong as square and rectangular pipe. Some agricultural machinery skeleton, steel and wood furniture are commonly used square and rectangular pipe.

焊缝是用一对滚盘电极代替点焊的圆柱形电极,与工件作相对运动,从而产生一个个熔核相互搭叠的密封焊缝的焊接方法。

The welding seam is a kind of welding method that uses a pair of disc electrodes instead of spot welding cylindrical electrodes to move relative to the workpiece, thus producing a sealed weld with overlapping nuggets.

方管的性能指标

Performance Index of Square Tube

塑性:是指金属材料在载荷作用下,产生塑性变形(永久变形)而不破坏的能力。

Plasticity: refers to the ability of metal materials to produce plastic deformation (permanent deformation) without destroying under load.

硬度:是衡量金属材料软硬程度的指针。常用的方法有布氏硬度(HB)、洛氏硬度(HRA、HRB、HRC)和维氏硬度(HV)等方法。

Hardness: It is a pointer to measure the degree of hardness and softness of metal materials. Common methods include Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) and Vickers hardness (HV).

疲劳度:机器零件在循环载荷下工作的,在这种条件下零件会产生疲劳。

Fatigue: Machine parts work under cyclic loads, under which conditions parts will produce fatigue.

冲击韧性:以很大速度作用于机件上的载荷称为冲击载荷,金属在冲击载荷作用下抵抗破坏的能力叫做冲击韧性。

Impact toughness: The load acting on the machine parts at a great speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness.

强度:强度是指金属材料在静荷作用下抵抗破坏(过量塑性变形或断裂)的性能。

Strength: Strength refers to the resistance of metal materials to failure (excessive plastic deformation or fracture) under static load.

管理员

该内容暂无评论